Sustainable Aviation Fuel (SAF)

Air travel has changed our world for the better, enabling settlement of communities, fueling commerce, facilitating the exchange of goods and fostering relationships that could not have existed for previous generations. While air travel makes our world a smaller and better place, there are environmental costs associated with the energy needed for flight as a result of greenhouse gas (GHG) and particulate matter (PM) emissions. Virent’s SAF can help the aviation industry address these challenges by enabling a 100% ‘drop-in’ SAF with lower lifecycle GHG and lower PM emissions.

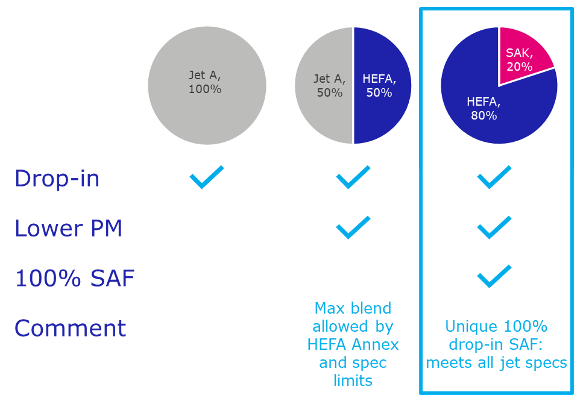

SAF is typically a blend of a renewable synthetic paraffinic kerosene (SPK) fuel and petroleum-based Jet A fuel. Current regulations limit the SPK that can be used in jet fuel to a maximum of 50%, as the SPK products lack compounds called aromatics that are necessary to meet current fuel specifications, and also do not have the density required to meet jet fuel specs. Virent’s synthesized aromatic kerosene (SAK) – derived from plant sugars – provides the necessary aromatics and density to the SPK fuel, eliminating the need for petroleum products and enabling production of a 100% ‘drop-in’ SAF that can be used in existing jet engines and infrastructure with no modifications. Virent has also done engine testing that shows a SAK blend has lower particulate matter (PM) emissions than conventional jet fuels because it has different aromatic compounds. The chart below demonstrates advantages of a 100% drop-in SAF (note HEFA is a type of SPK fuel)

Virent SAK fuel enabled the first commercial passenger flight in Dec. 2021, by United Airlines, that used 100% ‘drop-in’ SAF in one engine. Virent is continuing to work towards commercializing it’s SAK product and advance it through the ASTM approval process for new sustainable fuels.

Virent also has a separate SAF product composed of cycloparaffins called Synthesized Kerosene (SK) jet fuel product that is under development and completed laboratory and ‘fit for purpose’ testing in the ASTM certification process.

Read more about our testing demonstrating lower PM Emissions

Read more about the first commercial flight with 100% drop-in SAF