BioForming

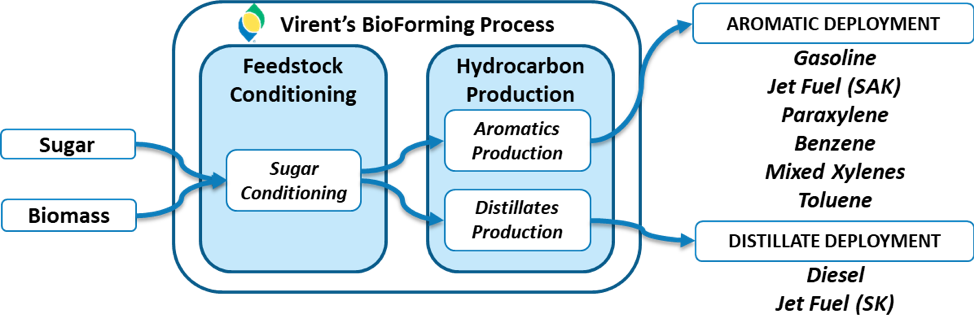

- Virent’s BioForming® process converts aqueous carbohydrate solutions into mixtures of “drop-in” hydrocarbons. The process has been demonstrated with conventional sugars obtained from existing sugar sources (corn wet mills, sugarcane mills, etc.) as well as a wide variety of cellulosic biomass sources. The process can accommodate a broad range of compounds derived from biomass, including C5/C6 sugars, polysaccharides, organic acids, furfurals and other degradation products generated from the deconstruction of biomass.

All of Virent’s hydrocarbon products from the BioForming processes are “drop-ins” for petroleum fuels and petrochemicals.

The BioForming Advantages

Drop-In, Premium Hydrocarbon Products

Virent’s hydrocarbon molecules are the same as those found in today’s petroleum products, but from renewable feedstocks. These molecules can be dropped in to existing infrastructure for the production of chemicals or blended in high concentrations to make premium quality gasoline, diesel or jet fuel with global market acceptance.

Feedstock Choice, Feedstock Change

Virent’s BioForming process accommodates the renewable feedstocks our customers require, based on their preferences for source, price, emissions targets, geographic location, availability or other obligation.

Responsible Environmental Stewardship

The BioForming process is energy efficient and has low life-cycle carbon emissions relative to fuels from crude oil. The BioForming process allows for efficient system heat integration along with reduced energy inputs as it produces hydrocarbon products that naturally separate from water.

Increased Scalability

The BioForming process resembles catalytic processes now used in petroleum refining, leading to greater probability of acceptance and greater potential for scalability than competing technology pathways.